Stainless Steel Electric Heating Reactor Selection: A Comprehensive Guide to Choosing the Right Equipment

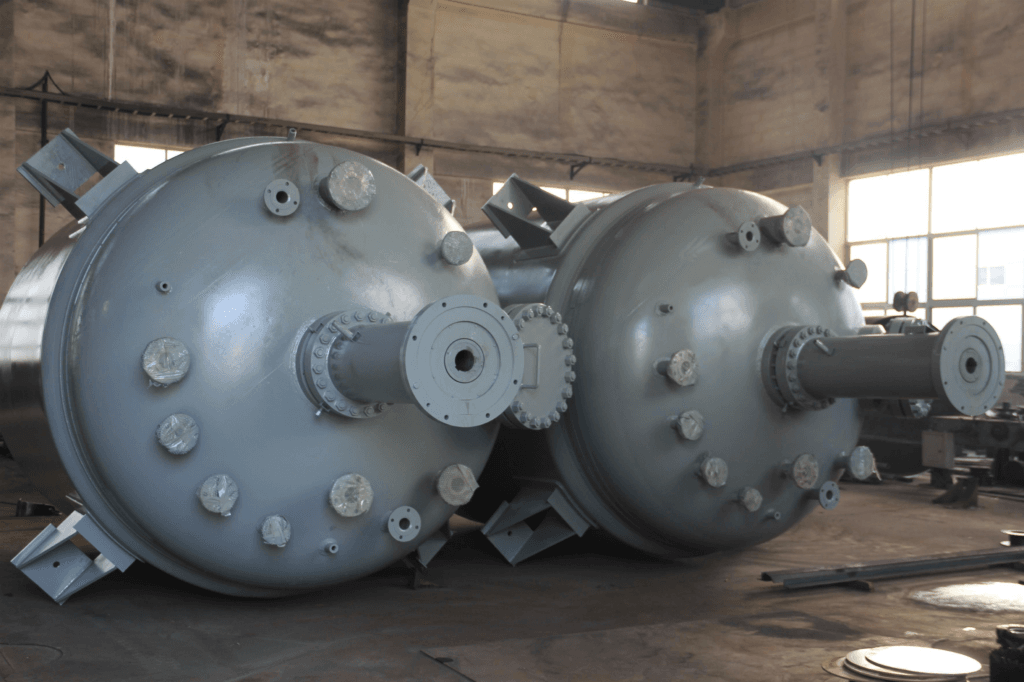

Selecting the right stainless steel electric heating reactor for your industrial or laboratory needs can significantly impact the efficiency and reliability of your processes. These reactors are widely used in various industries, including pharmaceuticals, food production, and chemical manufacturing. The stainless steel electric heating reactor selection process requires careful consideration of various factors such as reactor size, material quality, heating capabilities, and stirring efficiency. This article provides an in-depth guide to making an informed decision, with a focus on the AKGF-200L Stainless Steel Reactor by EquilRxnLab, a leading choice for large-scale chemical processes.

Factors to Consider When Choosing a Stainless Steel Electric Heating Reactor

When selecting a stainless steel electric heating reactor, it is essential to evaluate several factors to ensure you are choosing the right equipment for your specific requirements. Below are the key considerations:

1. Reactor Volume and Capacity

The volume of the reactor determines the scale of chemical processes it can accommodate. For larger-scale processes, it is crucial to choose a reactor with the appropriate capacity. For example, the AKGF-200L Stainless Steel Reactor features a 200L reaction volume, making it suitable for large-scale chemical operations that require substantial batch sizes.

2. Material Quality

The durability and resistance to corrosion of the reactor are critical for maintaining the integrity of your processes. Stainless steel is the preferred material due to its excellent corrosion resistance and longevity. The AKGF-200L is available in both 304 and 316 stainless steel options, offering enhanced corrosion resistance, especially in harsh chemical environments.

3. Stirring Efficiency

Effective mixing is crucial for uniform reaction and optimal process results. The reactor must be equipped with a powerful stirring mechanism. The AKGF-200L Stainless Steel Reactor includes a high-speed stirring system with a motor capable of reaching speeds from 0 to 450 RPM. This ensures efficient mixing, even for high-viscosity materials, improving the overall efficiency of the chemical reaction.

4. Heating and Cooling Control

The temperature control system is another vital factor in reactor selection. A jacketed design allows for precise control of heating and cooling during the reaction process, preventing overheating or underheating of materials. The AKGF-200L Stainless Steel Reactor features a jacketed design that provides efficient temperature regulation, ensuring that the reaction conditions remain stable.

5. Customization Options

Depending on the nature of the process, customization options may be necessary. The AKGF-200L offers customizable kettle diameters and agitator shafts, allowing users to tailor the reactor to meet specific processing needs. This flexibility ensures that the reactor can handle a wide range of materials and processing conditions.

Why Choose the AKGF-200L Stainless Steel Reactor?

The AKGF-200L Stainless Steel Reactor from EquilRxnLab stands out as a top choice for those requiring high-performance reactors for large-scale chemical processes. Some of the standout features of this reactor include:

- 200L Reaction Volume: Ideal for large-scale operations.

- Stainless Steel Construction: Available in corrosion-resistant 304 and 316 stainless steel.

- High-Speed Stirring (0-450 RPM): Ensures efficient mixing with a 750W motor.

- Jacketed Design: Offers precise heating and cooling control.

- Customization Options: Adjustable kettle diameter and agitator shaft for specific needs.

For more details, visit the product page or check out the EquilRxnLab product catalog.

Conclusion: Enhancing Chemical Processes with the Right Stainless Steel Electric Heating Reactor

When choosing a stainless steel electric heating reactor, considering factors such as reactor volume, material quality, stirring efficiency, heating control, and customization options is essential. The AKGF-200L Stainless Steel Reactor by EquilRxnLab offers an excellent balance of performance, durability, and flexibility, making it a top choice for large-scale chemical processes.

For more information or to purchase the AKGF-200L, please visit EquilRxnLab Contact Us or explore our YouTube channel, Instagram, and Facebook for updates.