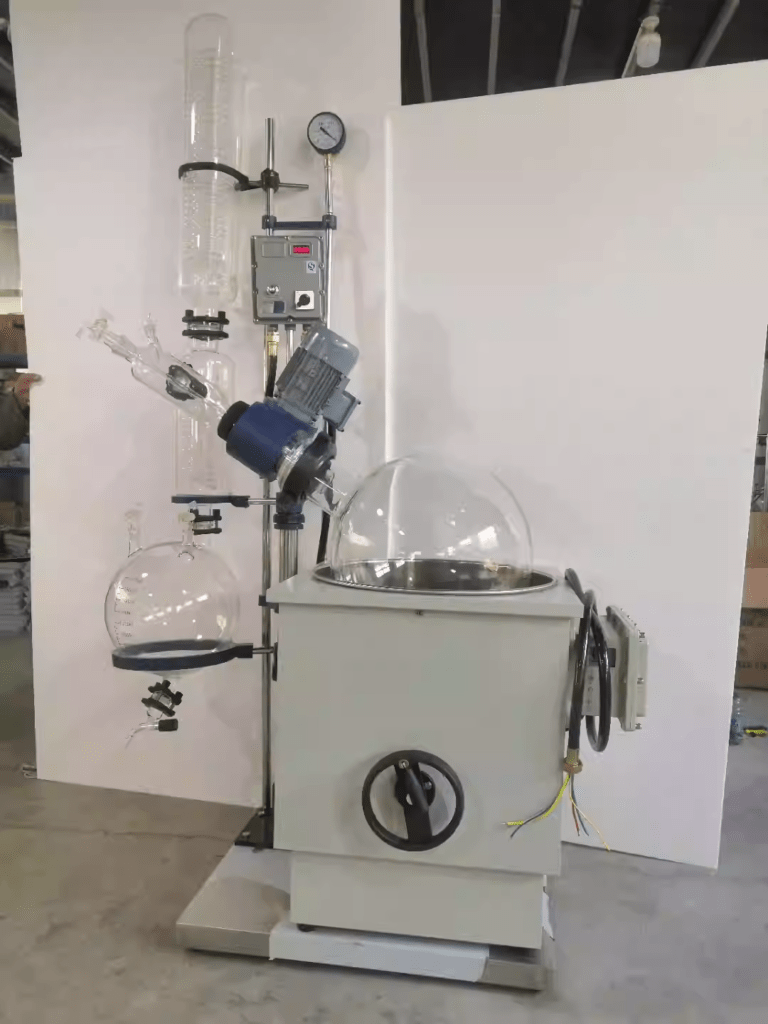

With the rapid advancement of nanotechnology, mesostructured materials have shown great potential in catalysis, sensors, and optoelectronic devices. The application of rotary evaporators plays a crucial role in this field. Particularly in the synthesis of silica nanowires, rotary evaporators not only accelerate the evaporation of solvents but also improve the quality and structural stability of the nanowires. This article explores how rotary evaporators are used in the synthesis of silica nanowires in porous alumina membranes and how they enhance experimental efficiency and precision.

Porous Alumina Membranes and Their Role in Nanowire Synthesis

Porous alumina membranes are ideal templates for synthesizing ordered nanostructures due to their periodic pore structure, which can guide the growth direction of nanomaterials. In the synthesis of silica nanowires, porous alumina membranes direct the deposition of silica precursors into the pores. Through sol-gel processes and other techniques, silica precursor solutions are injected into the alumina membrane pores, and after heat treatment or chemical reactions, stable silica nanowires are formed.

The Application of Rotary Evaporators in Silica Nanowire Synthesis

During the synthesis of silica nanowires, sol-gel methods are commonly used to inject silica precursor solutions into the pores of porous alumina membranes. The application of rotary evaporators is critical in this process, especially in solvent removal and precursor concentration steps. Rotary evaporators, through a combination of rotation and heating, make solvent evaporation more efficient while reducing the solvent’s boiling temperature, preventing damage to the solution components.

- Solvent Evaporation and Recovery

In the sol-gel process, the silica precursor solution needs to undergo evaporation to remove the solvent and form a gel precursor. The application of rotary evaporators accelerates solvent evaporation while recovering the solvent via a condenser, ensuring efficient solvent recovery and reducing waste. - Uniform Concentration

The rotating feature of the rotary evaporator allows the solution to form a thin film in the heating bath, significantly increasing the contact area between the solvent and air. Application of rotary evaporators ensures uniform evaporation of the solvent, preventing local overheating and uneven evaporation, which helps ensure that the silica precursor is deposited uniformly in the alumina membrane, leading to the formation of stable silica nanowires.

Other Applications of Rotary Evaporators

The application of rotary evaporators is not limited to nanowire synthesis. Its wide range of uses in laboratories makes it an indispensable piece of equipment. Some common application areas include:

- Pharmaceutical Research

In the pharmaceutical industry, application of rotary evaporators is common for drug purification, solvent removal, and concentration. Its efficient solvent recovery system helps improve solvent recovery rates and reduces costs in the research process. - Food and Natural Product Extraction

Application of rotary evaporators in food and natural product extraction allows for effective solvent removal while maintaining the stability of heat-sensitive compounds. This feature is especially important in the extraction of essential oils or natural pigments. - Environmental Analysis

In environmental studies, application of rotary evaporators is widely used for concentrating samples such as water or soil, aiding in accurate testing and analysis.

Structural Characterization and Performance Analysis

After synthesizing the silica nanowires, researchers typically use techniques like Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM) to analyze the morphology, structure, and performance of the nanowires. The application of rotary evaporators in solvent removal and precursor concentration can significantly influence the morphology and quality of the final product.

- Scanning Electron Microscopy (SEM): Used to observe the surface morphology and size of the silica nanowires.

- Transmission Electron Microscopy (TEM): Provides higher-resolution images for detailed internal structure analysis of the nanowires.

- X-ray Diffraction (XRD): Used to analyze the crystallinity of silica and determine whether the desired amorphous or crystalline structure has been formed.

The application of rotary evaporators plays a vital role in the synthesis of silica nanowires through the sol-gel process, especially in solvent evaporation, concentration, and recovery. By ensuring efficient solvent removal and uniform precursor concentration, rotary evaporators help researchers better control the synthesis process, improving the quality and performance of the nanowires. Additionally, rotary evaporators are invaluable in pharmaceutical research, food extraction, environmental analysis, and many other fields.

For more information about the application of rotary evaporators, or to learn more about the AKRE-2000A LCD Display Lift Rotary Evaporator, please visit our website: AKRE-2000A Rotary Evaporator.