Introduction to High-Pressure Reactors

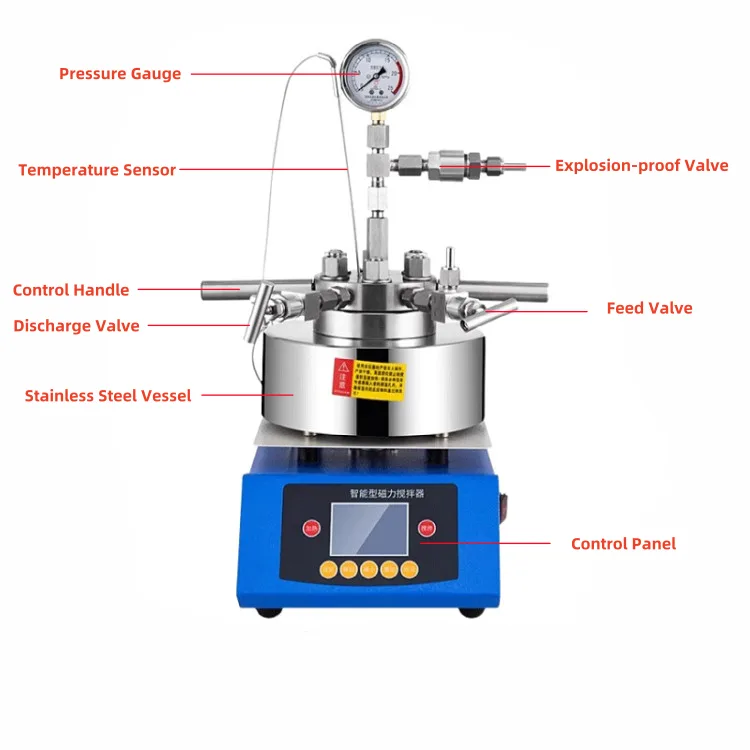

High-pressure reactors are essential for conducting chemical reactions that require elevated pressure and temperature conditions. The TGYF-B High Pressure Reactor with Magnetic Stirrer, manufactured by EquilRxnLab, stands out as a powerful tool designed to meet the needs of industries such as pharmaceuticals, chemicals, and materials science. This reactor offers precise control over both pressure and stirring conditions, ensuring optimal reaction environments for various applications.

Understanding the TGYF-B High Pressure Reactor with Magnetic Stirrer

The TGYF-B High Pressure Reactor with Magnetic Stirrer is specifically designed to enable high-pressure chemical reactions with excellent mixing capabilities. Featuring a magnetic stirrer, this reactor ensures uniform distribution of reactants, crucial for accurate and reproducible results in high-pressure environments. Built for both research and production environments, it can be employed in a wide array of chemical synthesis, polymerization, and other high-pressure applications.

Key Features and Specifications

- Model and Reactor Volume

The TGYF-B reactor is available in various sizes, offering volumes ranging from 50ml to 500ml. This allows for flexibility in conducting small-scale laboratory experiments or larger-scale synthesis projects. The reactor volume options include 50ml, 100ml, 250ml, and 500ml, making it adaptable to various research needs. - Pressure Range

The reactor is capable of operating at pressures up to 22 MPa, which makes it suitable for reactions that require elevated pressures to achieve optimal results. This wide pressure range supports a variety of chemical processes, including hydrogenation and polymerization, where high-pressure conditions are crucial. - Temperature Range

The TGYF-B reactor features an impressive temperature range from 0°C to 350°C, providing excellent control over reaction conditions. This wide operating range makes it ideal for a broad spectrum of reactions, from low-temperature reactions to those requiring high heat for efficient product formation. - Adjustable Stirring Speed

The reactor comes with adjustable stirring speeds of 0–1800 rpm, allowing for precise control over the mixing process. This flexibility is particularly important for reactions that require gentle or high-intensity stirring, depending on the nature of the chemicals involved. - Modular Electric Heating

The reactor employs modular electric heating, which ensures precise and uniform heating of the reaction mixture. The heating power varies based on the reactor volume:- 0.6 kW for volumes ranging from 50ml to 250ml

- 1.5 kW for the 500ml reactor

This energy-efficient heating system allows for rapid and consistent temperature control throughout the experiment.

- Magnetic Stirring Method

The TGYF-B reactor uses bottom magnetic stirring, which is an effective and reliable method for mixing reactants. This stirring system ensures that even viscous or challenging compounds are uniformly mixed, improving the efficiency and reliability of reactions. - Material and Durability

The reactor is constructed with high-quality stainless steel (304 & 316), making it highly resistant to corrosion and capable of withstanding the stresses of high-pressure environments. This durable material ensures long-lasting performance and reliability even under extreme reaction conditions. - Real-Time Monitoring and Control

The reactor is equipped with a digital screen display that provides real-time monitoring of temperature, pressure, stirring speed, and other critical parameters. This display enables researchers and operators to track the status of the reaction, making it easier to make adjustments as necessary and ensure optimal conditions are maintained. - Flange Connection

The TGYF-B High Pressure Reactor uses flange connections for secure and leak-proof assembly, ensuring safety and stability during high-pressure operations. These connections simplify setup and maintenance while ensuring safe operation during demanding reactions.

Applications of the TGYF-B High Pressure Reactor with Magnetic Stirrer

The TGYF-B High Pressure Reactor is suitable for a range of applications where precise pressure, temperature, and mixing control are essential. Its versatility makes it applicable across several industries:

- Chemical Synthesis

The reactor is extensively used in chemical synthesis, particularly for reactions that require controlled environments such as hydrogenation, oxidation, and polymerization. The precise temperature and pressure control ensure that reactions are conducted under optimal conditions, leading to higher yields and improved product quality. - Pharmaceutical Manufacturing

In the pharmaceutical industry, high-pressure reactors are key to producing active pharmaceutical ingredients (APIs) and intermediates. The TGYF-B High Pressure Reactor ensures that reactions are carried out safely and efficiently, supporting the development of new drugs and therapies. - Material Science Research

The reactor is ideal for material science applications, including the synthesis of new materials, catalysts, and polymers. By providing high pressure and temperature control, the TGYF-B reactor enables researchers to tailor materials with specific properties for use in various advanced technologies. - Environmental and Green Chemistry

The TGYF-B High Pressure Reactor is also useful in environmental and green chemistry research, such as the development of sustainable chemical processes, biofuel production, and carbon capture methods. Its high-pressure capabilities support reactions that drive eco-friendly innovations.

Why Choose the TGYF-B High Pressure Reactor with Magnetic Stirrer?

The TGYF-B High Pressure Reactor with Magnetic Stirrer offers several advantages that make it the ideal choice for a variety of high-pressure applications:

- Precise Control: The reactor’s advanced temperature, pressure, and stirring control features ensure reliable, reproducible results.

- Versatility: With a range of available volumes and heating capacities, the reactor is suitable for both small-scale research and larger industrial applications.

- Safety and Durability: Constructed with high-quality stainless steel and equipped with essential safety features, the reactor ensures safe operation under extreme conditions.

- Efficient Mixing: The magnetic stirring system ensures uniform mixing of reactants, enhancing the efficiency of the reaction and ensuring consistent results.

Explore the TGYF-B High Pressure Reactor with Magnetic Stirrer

For more information on the TGYF-B High Pressure Reactor with Magnetic Stirrer and to see its features in action, visit EquilRxnLab’s product page. For video demonstrations and further insights, check out EquilRxnLab’s YouTube channel.