Understanding the Importance of a 100L Double Layer Stainless Steel Reactor

In industrial chemical processing, having the right equipment can significantly influence the quality and efficiency of production. The 100L Double Layer Stainless Steel Reactor has emerged as an essential tool for industries engaged in processes that require precision, temperature control, and consistent results. With applications spanning from pharmaceuticals to food production, the double-layer structure of this reactor provides both versatility and reliability, making it a key asset in a variety of fields.Understanding the Importance of a 100L Double Layer Stainless Steel Reactor

In industrial chemical processing, having the right equipment can significantly influence the quality and efficiency of production. The 100L Double Layer Stainless Steel Reactor has emerged as an essential tool for industries engaged in processes that require precision, temperature control, and consistent results. With applications spanning from pharmaceuticals to food production, the double-layer structure of this reactor provides both versatility and reliability, making it a key asset in a variety of fields.

Key Features of the 100L Double Layer Stainless Steel Reactor

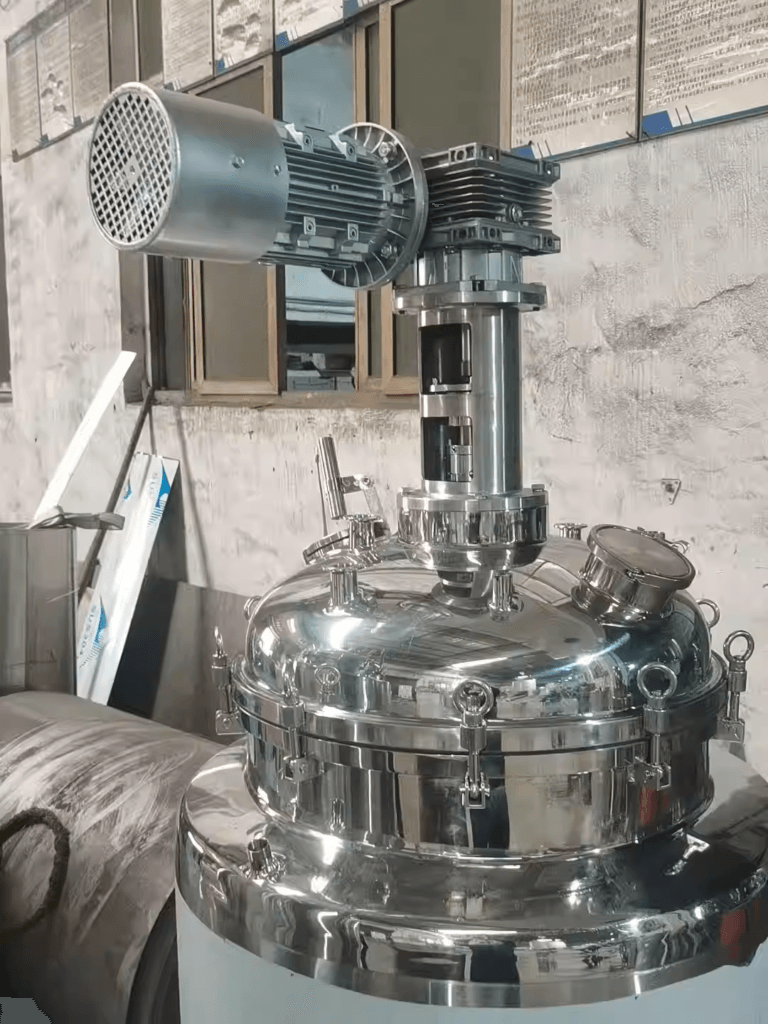

The 100L Double Layer Stainless Steel Reactor, as its name suggests, consists of two layers of stainless steel. This design offers multiple advantages, particularly in enhancing the efficiency of chemical reactions and maintaining a stable environment for sensitive processes. Some of the standout features include:

- Double Layer Design for Enhanced Heat Transfer: The inner layer of the reactor is designed to hold the reaction mixture, while the outer layer typically contains a cooling or heating medium. This dual-layer system facilitates efficient heat exchange, ensuring that the temperature of the reactor remains controlled throughout the process. This is crucial for reactions that require precise temperature control to maintain product quality and consistency.

- Durability and Corrosion Resistance: Made from high-quality stainless steel, the reactor is resistant to corrosion, making it ideal for handling a wide range of chemicals. The material’s strength and resistance to harsh conditions ensure that the reactor maintains its performance and longevity, even in demanding industrial environments.

- Precision Control: The reactor comes with advanced control systems that allow operators to monitor and adjust parameters such as pressure, temperature, and mixing speed. This level of control is essential for industries where maintaining specific conditions is critical to achieving the desired product outcome.

- Versatile Applications: The 100L Double Layer Stainless Steel Reactor is versatile enough to be used in various applications, including chemical synthesis, solvent extraction, mixing, and distillation. Its adaptability makes it suitable for industries such as pharmaceuticals, petrochemicals, food processing, and environmental engineering.

The Role of the 100L Double Layer Stainless Steel Reactor in Chemical Processes

The functionality of the 100L Double Layer Stainless Steel Reactor lies not only in its design but also in its ability to facilitate a range of chemical processes. In industries like pharmaceutical manufacturing, precise chemical reactions are paramount to producing safe and effective products. By providing excellent temperature control and mixing capabilities, the reactor helps ensure that these reactions proceed under optimal conditions.

Similarly, in the food industry, the reactor plays a crucial role in processes like extraction and concentration, where maintaining the integrity of the product is essential. The reactor’s versatility also extends to the petrochemical industry, where it can be used for refining processes that require high levels of accuracy and consistency.

Benefits of Using the 100L Double Layer Stainless Steel Reactor

When considering the purchase of a 100L Double Layer Stainless Steel Reactor, it is essential to evaluate the various benefits it brings to your operations. The primary advantages include:

- Increased Efficiency: With its efficient heat exchange system, the reactor reduces energy consumption and increases process efficiency. This translates into faster production times and lower operational costs.

- Improved Product Quality: Consistent temperature control and the ability to fine-tune reaction parameters result in higher-quality products. For industries that rely on precision, such as pharmaceuticals and food production, this reactor ensures that each batch meets strict quality standards.

- Cost-Effectiveness: While the initial investment in high-quality reactors may seem significant, the long-term benefits of increased productivity, reduced waste, and extended equipment lifespan make it a cost-effective choice for industrial applications.

- Safety: The reactor is equipped with multiple safety features, such as pressure relief valves and temperature monitoring systems, ensuring that any potential hazards during the chemical processes are mitigated.

Applications of the 100L Double Layer Stainless Steel Reactor

The versatility of the 100L Double Layer Stainless Steel Reactor allows it to be used in a variety of industrial applications:

- Pharmaceutical Industry: In the pharmaceutical industry, precise control over reaction conditions is vital for producing drugs and chemicals that meet stringent regulatory standards. The reactor supports processes such as drug synthesis and formulation, ensuring product safety and efficacy.

- Petrochemical Industry: The reactor can be used for refining and chemical conversion processes, where exact temperatures and mixing conditions are essential for high-quality output.

- Food and Beverage Production: From extracting essential oils to concentrating flavors, the 100L Double Layer Stainless Steel Reactor is perfect for processes requiring heat-sensitive operations, providing consistent results.

- Environmental Engineering: The reactor is also beneficial in environmental applications, such as waste treatment and bioreactor systems, where its capacity to manage chemical reactions and temperatures ensures effective and safe processes.

EquilRxnLab’s Commitment to Excellence

At EquilRxnLab, we understand the importance of having reliable, high-performance equipment to support complex industrial processes. Our 100L Double Layer Stainless Steel Reactor is designed to meet the highest standards of quality and functionality, ensuring that your operations run smoothly and efficiently. You can learn more about the product on our official page or watch a demonstration on our YouTube channel.

A Reliable Solution for Industrial Needs

The 100L Double Layer Stainless Steel Reactor is an essential tool for any industry requiring precision and efficiency in its chemical processes. Its robust design, excellent heat transfer capabilities, and versatile applications make it a standout solution for industries ranging from pharmaceuticals to food production. With advanced control systems and high durability, it provides a reliable and cost-effective solution for enhancing productivity and ensuring high-quality outcomes.

By investing in advanced reactors like the 100L Double Layer Stainless Steel Reactor, industries can improve operational efficiency, enhance product quality, and ultimately achieve better results in their processes.